Modern businesses operate in an environment that is rapidly changing and also becoming complex to operate in. As a result, businesses are required to manage increased consumer expectations, strict regulations, global supply chains, and interconnected systems. For a company to effectively manage these demands and operate efficiently, it cannot use traditional ways of monitoring operations and planning. Traditional tools like manual forecasting, occasional audits, and static reports are no longer effective at providing the insights needed to help the business predict the future and make informed decisions. Instead, these methods leave many businesses reacting to issues after they occur rather than preventing them in advance. All the above challenges can be effectively addressed using Digital Twin Technology. A digital twin is a virtual copy of the entire business processes, business operations, and a real-world asset. This digital version is regularly updated using real-time data collected from technologies such as sensors, software systems, and operational platforms. As a result, the digital model is connected to real-world conditions, informed by real-world data fed into it. This enable entities to test different scenarios and monitor performance without interfering with the entity’s actual operations. In this way, companies can identify weaknesses in their systems, explore how systems behave, and forecast the effects of changes before making real-world decisions. This helps an entity plan for improvements, respond quickly to abrupt disruptions, and reduce errors.

Digital twins have emerged as the most critical tools for decision-making, as most businesses currently rely on data to make decisions, innovate, and improve efficiency. It helps a business easily predict problems before they happen, use its resources effectively, and reduce operational risk. Digital twins turn complex data into actionable insights, allowing businesses to shift from guesswork to confident, data-driven strategies.

Understanding the Digital Twin Technology

Digital Twin Technology is an innovation that creates a digital version of a real-world asset, system, or business process. This digital version is designed to reflect how the real object or process behaves in everyday operations, as per Michael (2026). In the real world, digital twins are used by most entities to conduct simulations, identify potential problems, and analyze their performance. The digital twins are regularly updated with both real-time and historical data. By doing this, a company can observe how an asset or even various processes are performing at any given moment, rather than relying on outdated periodic reports.

A digital twin can support testing and analysis without disrupting real operations; in this way, organizations can run simulations, explore different scenarios, and predict possible outcomes in a virtual environment without affecting business operations. For instance, a company involved in the production of goods can test how performance is affected by changes in resource allocation before implementing them in the real world. This makes digital twins a practical and safe tool for improving efficiency, reducing risk, and supporting informed decision-making.

Components of Digital Twin Technology

For digital twins to work effectively, they use many technologies and features that connect the digital version to the real world. Here, each component plays a specific role in collecting data from the real world, continuously updating the digital version until the data is transformed into meaningful insights. A study by Vimal (2025) highlights the following components of the digital twins.

- Internet of Things (IOT) Sensors

A digital twin uses data collected from the real world to provide valuable insights. IoT sensors collect data from physical assets, environments, and machines. This data can include movement, pressure, temperature, energy usage, and operating states. The data provided here ensures that the digital twin reflects what is actually happening in the real world.

- Data Integration Layer

This component of digital twins gathers data from multiple sources, including sensors, enterprise systems, and operational databases. It then cleans, organizes, and standardizes the data to enable accurate analysis.

- Simulation Engine

This is the component of the digital twin that uses mathematical and logical models to simulate real-world behaviour and interactions; thus, it is core, as it enables the digital twin to behave like the real system it represents. Through simulations, organizations can test changes, explore scenarios, and evaluate outcomes without affecting physical operations.

- AI and Machine Learning Algorithms

One of the key features of digital twins is the ability to analyze data and provide valuable insights. This is done using artificial intelligence (AI) and machine learning (ML) algorithms. These two analyze data patterns and generate predictive insights. Thus, these tools help identify potential failures, forecast future performance, and recommend actions.

- Visualization Layer

This is the component of the digital twins where the results are now presented to different individuals in an organization in a way they can understand. Dashboards, charts, and 3D models enable users to monitor performance, identify trends, and interact with the digital twin. Using clear visual representations makes complex data accessible to decision-makers, even those without technical expertise, in a way they can easily understand.

Key Types of Digital Twins Used In Business

Digital Twin Technology is being applied in different forms depending on what a business wants to model, analyze, and optimize. As a result, they are categorized based on what they do and what they present. The following are the types of digital twins according to Oscar (2026)

- Product Digital Twins

These are digital twins used to represent individual products or physical assets throughout their lifecycles. They represent them from design and manufacturing through usage and maintenance. Different industries, such as manufacturing and engineering, use these digital twins to test designs, simulate real-world conditions, and identify potential failures before production.

- Performance Digital Twins

These digital twins are designed to monitor and optimize the performance of assets or systems over time. For these digital twins to work effectively, they depend on real-time data and analytics to monitor efficiency, forecast maintenance needs, and support performance improvement initiatives.

- Product Digital Twins

These are digital twins used to represent individual products or physical assets throughout their lifecycles. They represent them from design and manufacturing through usage and maintenance. Different industries, such as manufacturing and engineering, use these digital twins to test designs, simulate real-world conditions, and identify potential failures before production.

- Process Digital Twins

These types of digital twins, instead of focusing on physical objects, focus on operational processes and modelling workflows. They are mainly used in organizations to replicate how different business processes interact and respond to other variables. By doing so, entities can optimize resource allocation, identify obstacles, and enhance efficiency without interrupting live operations.

- System Digital Twins

It is a type of digital twin that is used to represent a group of interconnected assets or processes working together as a complete system. System twins enable organizations to understand complex interactions, assess system-wide risks, and evaluate the impact of changes at scale, making them especially valuable for large enterprises and infrastructure-intensive industries.

Read Also: Leveraging Artificial Intelligence for Small Business Success

How Digital Twins Work in Practice

Digital twins are virtual models that replicate the behaviour and characteristics of real-world objects, systems, or processes. This technology works by continuously receiving data from sensors and software systems, hence allowing the digital version to reflect what is happening in the physical world in real time. A study by Nick (2025) highlights the following steps on how digital twins work.

- Data Collection

Data is the foundation of the digital twin, enabling the virtual model to represent real-world conditions accurately. So, for a digital twin to work, it must first collect data. This is done with the help of sensors and connected devices that capture information such as temperature, speed, pressure, energy usage, or operating status.

- Virtual Modeling

When data is being collected, the goal is to create a digital copy of a real machine or process. This “virtual twin” behaves like the real thing, showing how its parts work, how much energy it consumes, and how it wears down over time. Instead of just being a picture, it becomes a working simulation you can test and learn from. For instance, a digital twin of a machine shows its parts, how much energy it uses, and how it wears down over time. This makes the model a working simulation instead of just a picture.

- Live Data Integration

A digital twin is helpful because it’s constantly updated with fresh data from the real machine. This means the model shows what’s happening right now. This real-time connection allows organizations to detect issues early, plan maintenance more effectively, and adjust operations as conditions change.

- Analysis and Simulation

Digital twins provide a safe and controlled environment for analysis and experimentation. Organizations can run simulations and test “what-if” scenarios without risking damage to tangible assets. Analytics and artificial intelligence tools further enhance this process by identifying trends, predicting outcomes, and highlighting potential risks.

- Decision-Making and Optimization

The final step involves using insights from the digital twin to improve performance and guide business decisions. Managers can rely on simulation results to select efficient strategies, reduce costs, and improve reliability. When integrated with enterprise systems, digital twins make it easier to implement improvements across production, logistics, and customer service. This turns data-driven insights into practical actions that deliver measurable business value.

Business Areas Transformed by Digital Twins

By providing real-time data insights and enabling data-driven decision-making, digital twins have changed how businesses operate. Digital twins are now applied across various industries to improve efficiency, support better decision-making, and reduce risk. A study by Cem (2025)

- Manufacturing

Digital twins are a key part of smart factories. They are used to create real digital models of production lines, equipment performance and factory layouts. By emulating production scenarios and monitoring machine health, businesses in the manufacturing industry can optimize workflows, reduce operational downtime, and improve product quality. Digital twins also support supply chain optimization by aligning production schedules with demand and supplier performance.

- Construction

Digital twins are used in the construction industry to facilitate planning, designing and project management. They apply this technology, in which the construction team create digital twins to visualize buildings and infrastructure projects before and during construction. These virtual models provide real-time updates on project progress, helping teams identify delays or issues early. Architects use 3D models with digital twins to check designs and make them more accurate. After a building is finished, managers rely on digital twins to watch things like temperature and air quality, helping save energy and keep people comfortable.

- Energy

The energy sector uses digital twins to support long-term planning and optimize the performance of complex assets. Digital twins help energy companies monitor asset conditions, predict maintenance needs, and evaluate operational changes in a safe virtual environment. This leads to improved reliability, lower operating costs, and more efficient use of resources.

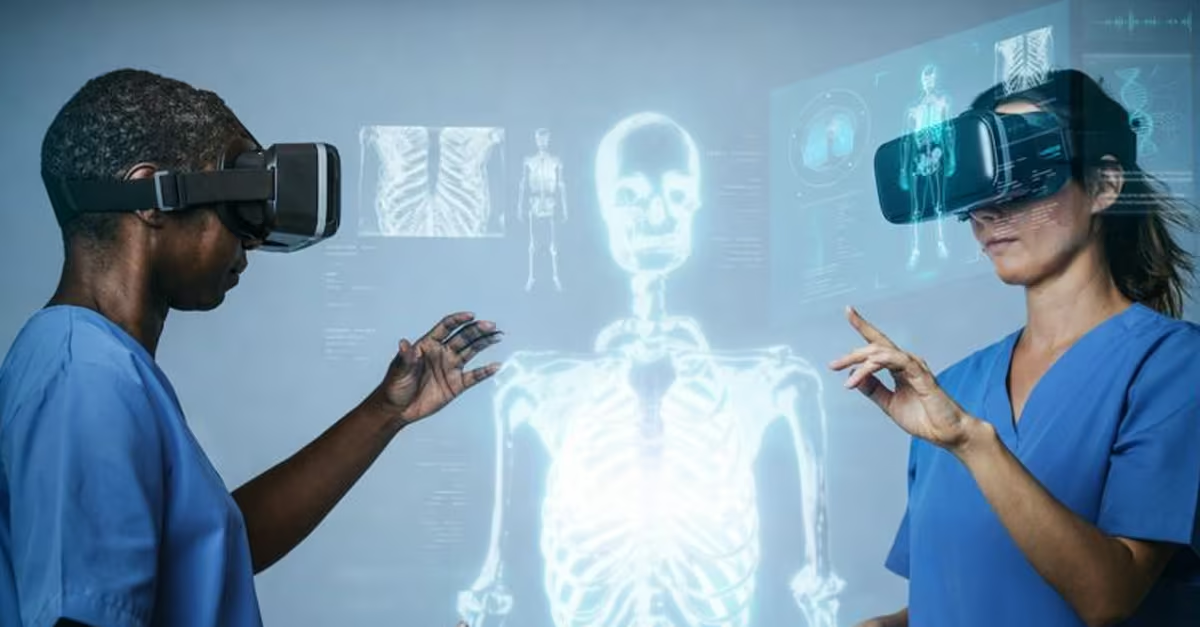

- Healthcare

Digital twin technology is increasingly used in healthcare to improve planning, treatment, and operational efficiency. Healthcare organizations create digital twins of hospitals, laboratories, and medical equipment to optimize workflows and resource use. In more advanced applications, digital twins of human organs or entire bodies are used to simulate how patients may respond to specific treatments. This supports more personalized care, better decision-making, and improved patient outcomes.

- Smart Cities

Digital twins are used to model urban infrastructure, including roads, utilities, buildings, and public services. City planners and administrators rely on these models to monitor infrastructure health, optimize traffic flow, manage energy consumption, and simulate the impact of urban development projects. This supports more sustainable, efficient, and resilient urban environments.

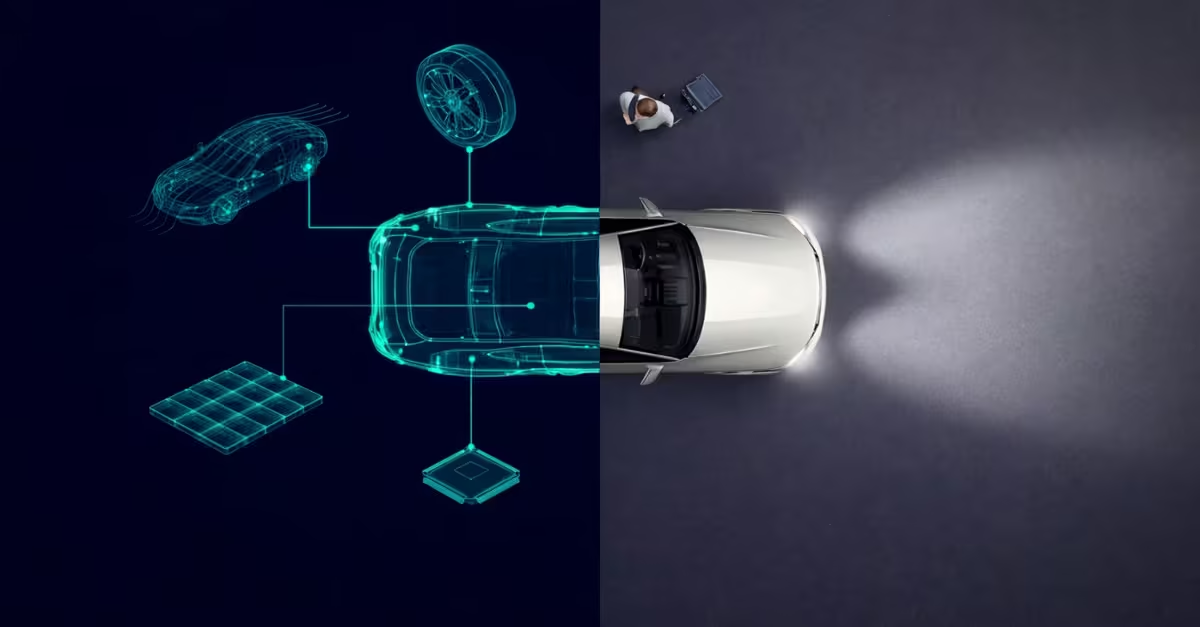

- Automotive

Digital twins are used in the automotive industry to create detailed digital models of vehicles and their components. These models combine mechanical, electrical, and software data to reflect how a car performs under real-world conditions. Digital twins are especially valuable for predictive maintenance, as they can identify potential issues before failures occur. This allows manufacturers, service centers, and vehicle owners to address problems early, improving safety and reliability.

Benefits Digital Twins Offer to Businesses

Businesses gain many benefits from using Digital Twin Technology, as it helps them turn their operational data into actionable insights. Digital twins enable a business to be proactive and make predictive decisions by replicating real-world assets and processes. The following are the reasons why businesses across industries are investing in this technology.

- Operational efficiency– one of the immediate benefits a business gets after investing in digital twins is streamlined operations. By enabling real-time monitoring of assets, workflows, and systems, businesses can detect barriers, optimize resource utilization and improve their processes, thus leading to more consistent operational performance across facilities and business units.

- Predictive maintenance- digital twins enable the business to predict equipment failures before they occur. This is due to this technology’s ability to analyze usage patterns, historical trends, and performance data to predict when malfunctions are likely to occur. This enables a business to schedule maintenance proactively, reducing unplanned outages and expensive emergency repairs.

- Innovation and product development– with the help of Simulation-based testing, digital twins facilitate innovations and product development. Digital twins enable businesses to prototype, test, and refine products in digital environments, thereby reducing reliance on physical prototypes. This reduces development cycles and costs, and prevents defects from reaching the market.

- Cost savings and return on investment (ROI) – a business can save on the cost of operation and increase its return on investment byimproving efficiency, reducing waste, and better capital planning. A business achieves this by simulating investment decisions and operational changes in a virtual environment to evaluate the financial impact before committing resources.

- Adapt Quickly to Market Changes – Market trends change very quickly, and businesses need to be ready to respond. With digital twin technology, organizations can adapt faster by testing new strategies in a virtual environment. This flexibility shortens decision-making cycles and gives companies a competitive edge in dynamic markets.

Read Also: Data-Driven Decision-Making for Businesses

Challenges and Limitations of Digital Twin Adoption

Even though digital twins are very useful, businesses face challenges when using them. Knowing these obstacles helps companies plan better, reduce risks, and find innovative ways to adopt the technology.

- High Implementation Costs

For a business to use digital twin technology, it requires a significant upfront investment in technologies such as sensors, cloud platforms, and data infrastructure. This becomes a barrier for businesses to afford, thus hindering the implementation of digital twin technology.

- Data Security and Privacy

Another critical concern in digital twins is protecting the collected data from unauthorized access. As digital twins depend on continuous data collection and integration across systems, they also involve sensitive operational and personal data. Without strong cybersecurity measures, businesses may be exposed to data breaches, especially in highly regulated industries such as healthcare and finance.

- Integration Complexity

In business, digital twin platforms must operate alongside legacy systems, such as accounting systems. Many entities rely on outdated infrastructure that was not designed for real-time data exchange or advanced analytics. As a result, it isn’t easy to integrate these systems with modern cloud-based and IoT-enabled platforms used in digital twin technology, hindering most organizations from adopting this technology.

- The Talent Gap

Developing, deploying, and maintaining digital twins requires expertise in data analytics, artificial intelligence, IoT, cloud computing, and domain-specific operations. Many organizations struggle to find or retain professionals with these combined skill sets, making it challenging to leverage digital twin technology.

Conclusion

As business operations have become more complex, traditional tools have failed to manage them effectively. Digital twins have become a powerful tool for changing how many businesses operate and solving problems that traditional tools were unable to. By creating real-time, data-driven virtual representations of physical assets, processes, and systems, digital twins provide organizations with deeper visibility, predictive insight, and the ability to test decisions before implementing them in the real world. By doing this, organizations enjoy many benefits, such as operational efficiency, high return on investment, encouragement of innovation, facilitation of proactive decision-making, such as predictive maintenance, and reduction. Different industries can use digital twins, such as the health industry to enable better planning and treatment by creating digital versions of hospitals, the manufacturing industry to facilitate smart factories, the construction industry to help project management and planning, and also in smart cities. Even with many benefits, digital twins are difficult to fully adopt in many organizations, as they face challenges such as a lack of human resources to operate this technology, difficulties integrating with existing business software, high initial costs, and weak cybersecurity systems in many businesses.